Local Chapters of the National Space Society

The National Space Society supports a global network of chapters that provide a voice for space in their community. In fact chapters are the heart of the National Space Society’s local outreach efforts – all made possible by the volunteers who have either started or joined chapters.

A chapter of the National Space Society is a group of space enthusiasts who have joined together for purposes of camaraderie, education, local activism via outreach activities, and possible political activity. The focus of a chapter is what its members make it. A chapter of the National Space Society has the same vision and mission as that of the Society.

- Support NSS space advocacy on the local and national level.

- Holds meetings, private or open to the public

- Sponsors exhibits and information booths as various venues, such as malls, conventions, libraries, etc.

- Educates their members and the public by bringing in speakers to meetings

- Provides speakers–maybe a speaker’s bureau–on a variety of Space Settlement & exploration topics to various local organizations, schools, civic groups, etc.

- Appears on radio and TV shows as “local Space experts”

- Visits, calls or writes letters to local Congressional representatives

- Teaches courses (continuing education, etc.).

- Co-sponsors Scouting Explorer Posts, Young SEDS Chapters or other youth groups.

- Operates a chapter website, hosts chats, a Facebook page, or other electronic media for space information.

- Studies or researches space topics or concepts.

- Hosts seminars, star parties, or other events.

- Provides speakers and support for local schools.

- Organizes or sponsors competitions dealing with space art, design, engineering, etc.

- Works in conjunction with other chapters or local organizations on special projects or celebrations: World Space Week, Moon Day, Yuri’s Night, conventions, etc.

- Raises funds via awards, rebates when recruiting new NSS members, and other methods allowed by their local government.

- Chapters bring space outreach to your community.

- Chapters are the ideal networking vehicle for space activists.

- Chapters provide individuals with opportunities for leadership and for affecting space policy.

- The more chapters the National Space Society has, the stronger our pro-space message will be.

- It’s fun to be in a community of space enthusiasts

To find out if there is a chapter near you, refer to our Find a Local Chapter page.

If you are a resident of the United States, please refer to Creating a new U.S. Chapter. All others should refer to Starting a new International Chapter. Additional information about resources is available on the Chapter Resources page. For additional information on starting a chapter, you should contact a member of the Chapters Committee or one of the district chapter coordinators. Contact information for coordinators is available on the Chapter Coordinators page.

Interactions of the national organization with the chapters is handled via the NSS Chapters Committee. The Chapters Committee is charged with the responsibility of fostering productive relations between chapters and between chapters and the National Space Society. It is comprised of volunteer NSS national leaders, and appointed volunteers from the chapters community, who serve in committee posts (such as District Coordinator), established to conduct Committee business. The committee monitors programs for and of chapters and makes recommendations on projects and programs to serve the mutual interests of NSS and its chapters. Appointments are subject to the approval of the NSS Executive Committee. The Chair of the Chapters Committee is David Stuart, who reports to the NSS Vice President of Chapters Larry Ahearn.

Chapter Annual Reports: With respect to formal reporting, all chapters are expected to complete an annual report to the Society. Details on how to comply with the reporting requirements are available on the Chapter Annual Reports page.

Chapters Assembly: A Chapters’ Assembly created by the chapters themselves exists to facilitate inter-chapter and chapter-Board communication. It holds regular free conference calls among the representatives elected from each member chapter. Although a separate entity, it reports to the NSS Board of Directors through the Chapters Committee.

Chapter News from the NSS Blog

Photo: Gibson’s first shuttle mission was the first to land at Kennedy Space Center. Credit: NASA By Robin Scott Robert “Hoot” Gibson is not only a

The National Space Society Iowa Chapter is providing an opportunity to hear from and meet with former NASA astronaut Commander Susan Kilrain. This will be

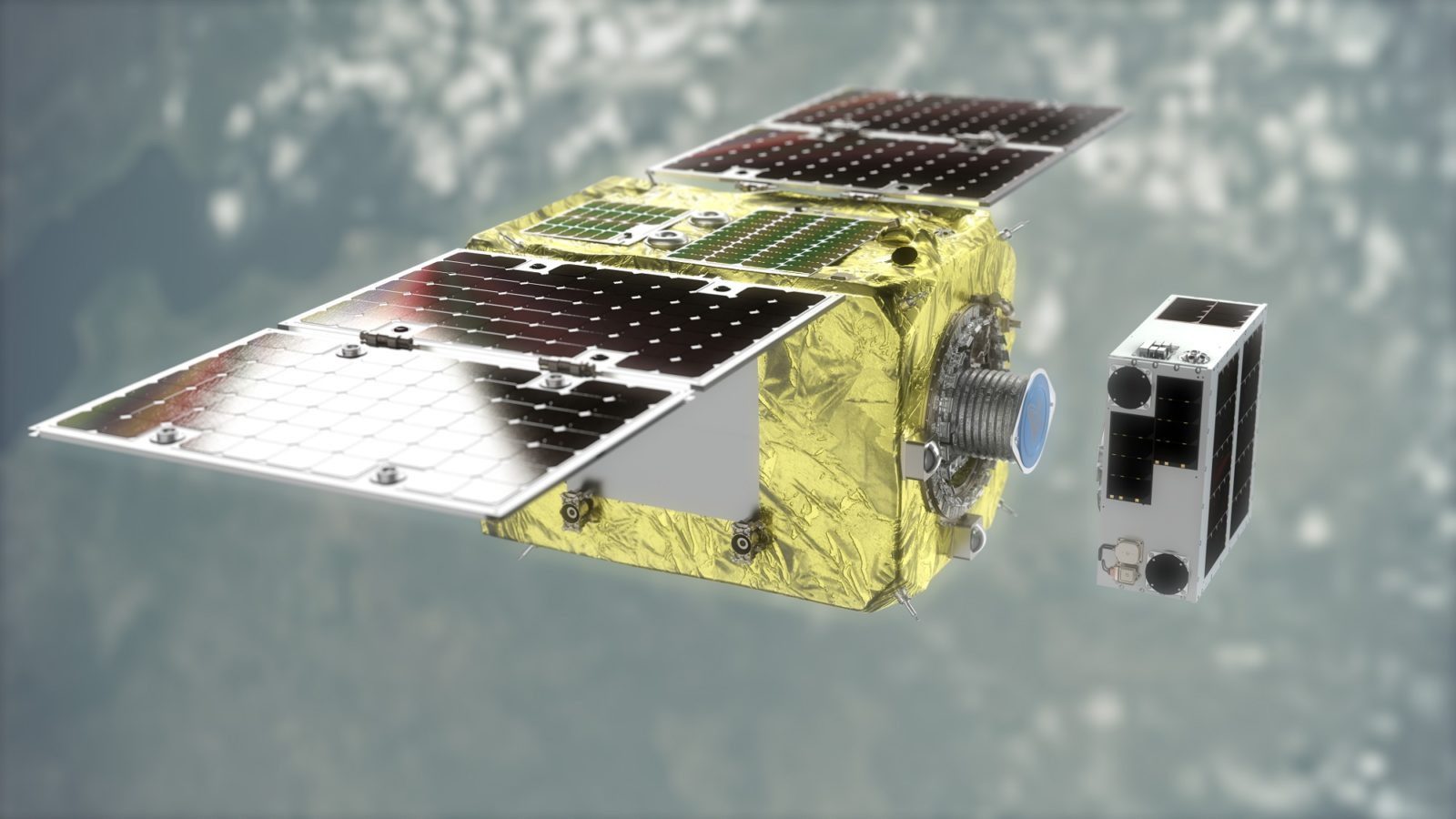

Event: An Introduction to Space Sustainability with Gene Fujii of AstroscaleDate and Time: Monday, February 26 at 5:30 p.m. Central TimeLocation: DMACC West Campus, 5959

By Robin Scott The NSS North Houston Chapter hosted Houston Air Traffic Controllers Holly Cron and Jesse Strickland who spoke on “How Air Traffic Control (ATC) Operations

Guest Speaker: Captain Robert “Hoot” GibsonDate and Time: Monday January 29, 5:30 p.m. CSTLocation: DMACC West Campus, 5959 Grand Ave., West Des MoinesJoin Zoom Meeting:

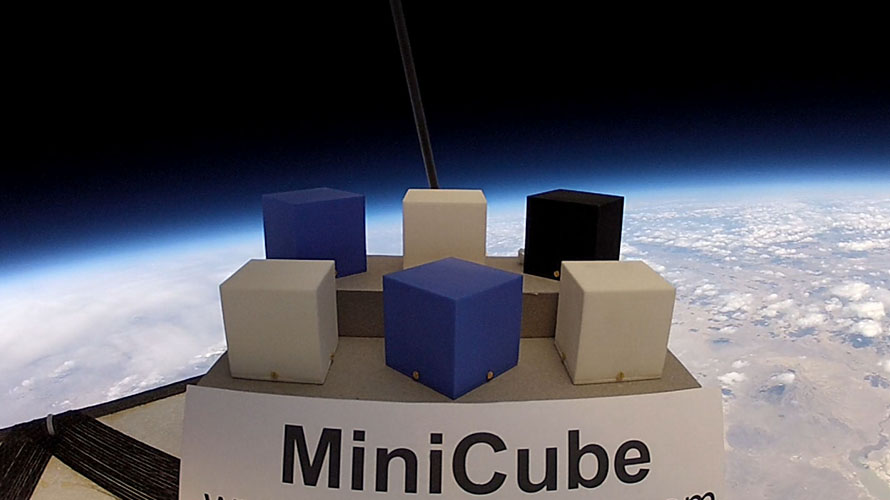

Free MiniCube Balloon Flights to the Upper Atmosphere Image courtesy JP Aerospace The Sacramento L5 Society (SacL5), one of the oldest continuous non-profit space advocacy

The NSS Iowa Chapter meeting presentation on October 16, available world-wide via Zoom, will feature speaker Dan Hoy, local NASA JPL Solar System Ambassador and

The NSS Iowa Chapter invites you to join them for a video presentation chronicling the contributions of Iowa-based Collins Radio (now Collins Aerospace) to the

Photo by Fred Becker As seen by Cliff McMurray Members of the NSS Chapter Oklahoma Space Alliance, Cliff and Claire McMurray, made the 14-hour drive from